COV CHEEB TSAM

- Kev Lag Luam

Kev Lag Luam

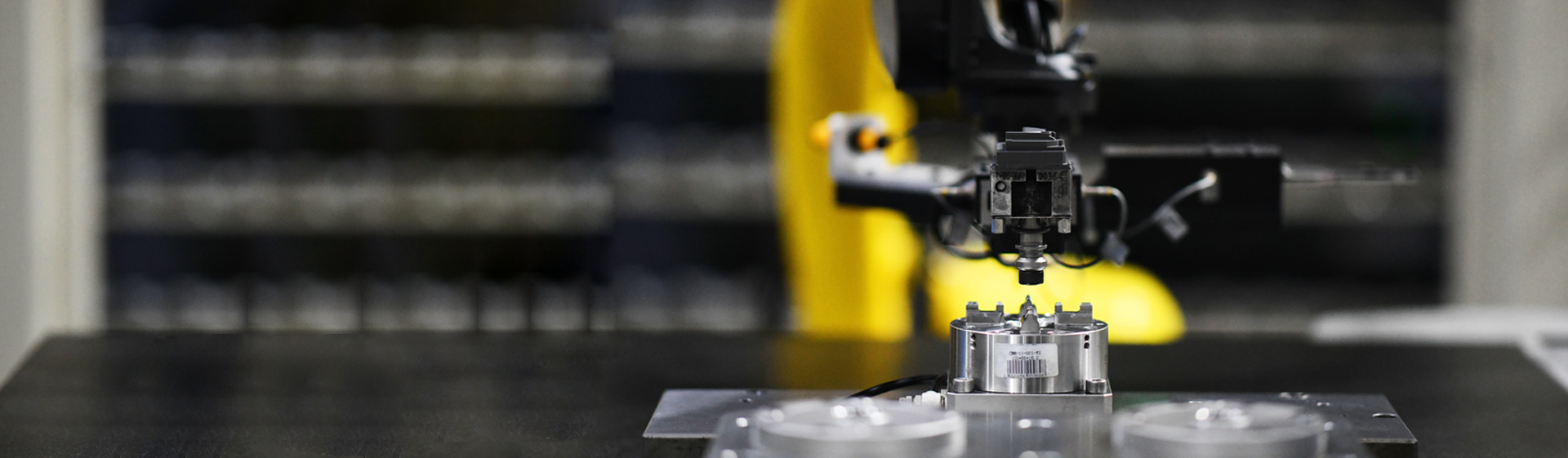

Hongrita tsom mus rau kev tsim cov khoom lag luam zoo rau cov neeg siv khoom, thiab cog lus tias yuav ua tus thawj coj hauv kev lag luam. Peb muaj cov khoom siv tsim khoom thiab thev naus laus zis siab heev, nrog rau pab pawg kws tshaj lij, tuaj yeem ua tau raws li ntau yam kev xav tau ntawm cov neeg siv khoom sai thiab raug.

Peb paub zoo txog qhov tseem ceeb ntawm cov neeg siv khoom xav tau thiab cov kev xav tau rau kev tsim khoom, yog li peb ua tib zoo saib xyuas cov ntsiab lus, tswj hwm txhua qhov txuas ntawm kev tsim khoom, kom ntseeg tau tias cov khoom raug thiab ntseeg tau. Tib lub sijhawm, peb kuj muab cov kev pabcuam tshwj xeeb rau cov neeg siv khoom, raws li cov kev xav tau thiab cov kev xav tau ntawm cov neeg siv khoom, tsim kom tau raws li lawv cov kev xav tau ntawm cov khoom lag luam.

Kev Lag Luam

Cov khoom lag luam ib txwm xav tau cov polymers ruaj khov nrog cov qauv pheej yig thiab ruaj khov. Nrog ntau tshaj 20 xyoo ntawm kev paub hauv kev tsim cov cuab yeej ntau yam thiab tsim cov khoom lag luam, Hongrita tshwj xeeb hauv kev overmolding thiab txaus siab rau nws tus kheej tsim lub rooj tig thiab sab-txhaj tshuaj uas ua kom zoo dua qhov kev hloov pauv ntawm peb cov tshuab txhaj tshuaj ib zaug kom daws tau qhov xav tau ntawm ob-koob thiab peb-koob txhaj tshuaj molding txheej txheem.

Ntxiv rau TPE, kev siv cov roj hmab Silicone roj hmab (LSR) overmolds Thermoplastic tau dhau los ua ib qho kev hloov pauv hauv xyoo tas los no rau cov khoom lag luam, tshwj xeeb tshaj yog rau cov ntawv thov ua haujlwm hauv qhov chaw ib puag ncig hnyav. Tsis tas yuav piav qhia txog qhov zoo ntawm LSR dhau TPE, Hongrita paub txog kev tsim cov cuab yeej bi-component rau Thermoplastic + LSR lossis LSR + LSR nrog rau cov hlau ntxig molding. Nws muab rau tus tsim khoom ntau tshaj plaws kom ua tiav lawv cov khoom nrog qhov kev nqis peev qis tshaj plaws nrog tsawg dua tom qab-molding kev ua haujlwm theem nrab.